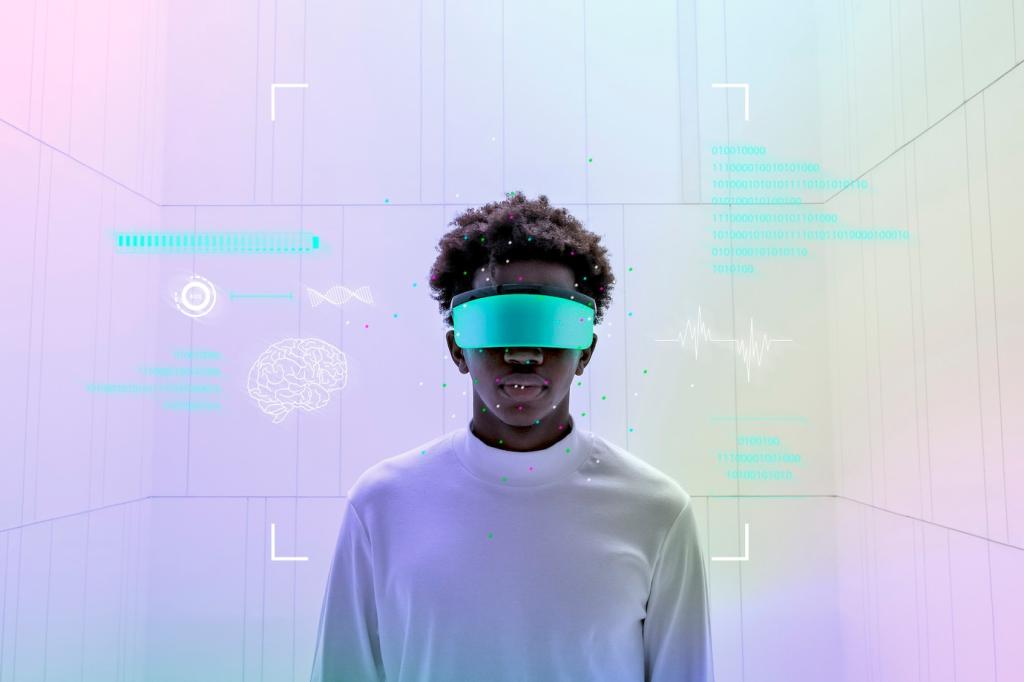

AR/VR for Installation, QA, and Training

With AR headsets, installers align modules to holographic guides that highlight anchor points, clearances, and cable routes. One crew shaved hours off a rooftop MEP connection because the overlay revealed a clash minutes before bolts were tightened. That small save prevented a weekend of costly rework.

AR/VR for Installation, QA, and Training

Design leads join from anywhere, mark up the live model, and approve adjustments without stepping on-site. Clients see exactly what will be built, not just abstract drawings. The result is fewer surprises, friendlier conversations, and a measurable uptick in first-time-right installations on demanding, high-visibility projects.

AR/VR for Installation, QA, and Training

VR lets apprentices practice complex lifts and tight tolerances before touching a single crane hook. The first time they face a real module, muscle memory already knows the choreography. Share your training stories in the comments, and we’ll compile a guide to proven, budget-friendly XR setups.