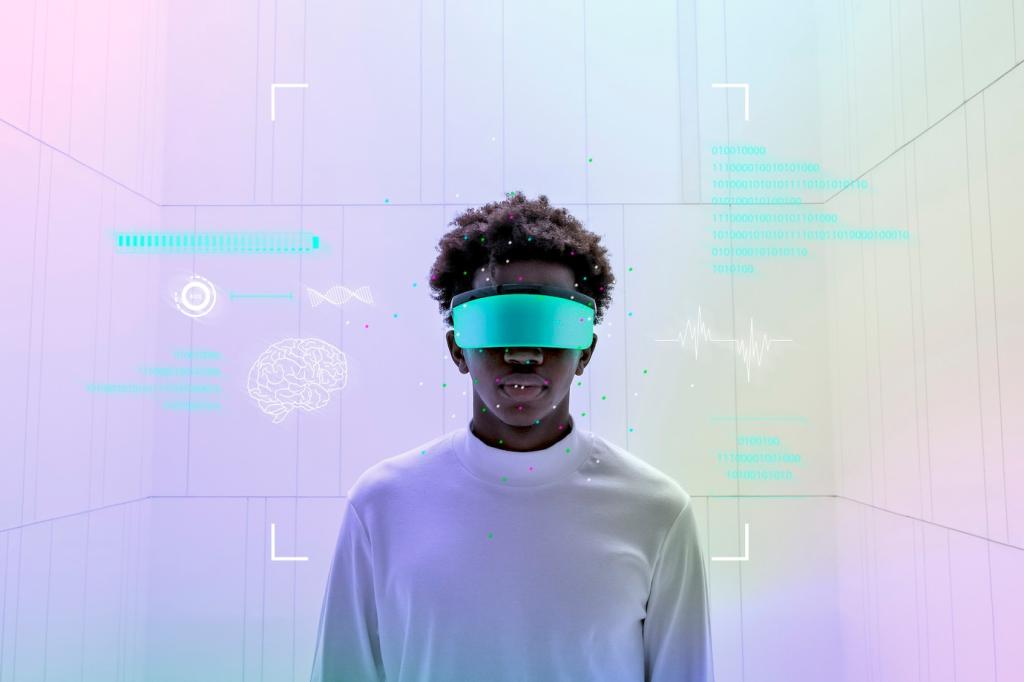

The Role of AI in Modular Building Design

Chosen theme: The Role of AI in Modular Building Design. Explore how intelligent tools accelerate concepts, align fabrication realities, reduce waste, and enable adaptable spaces. Join the conversation, subscribe for field notes, and share your toughest constraints to help train better design prompts.

Generative Beginnings: Concept Design Reimagined

Multi-objective solvers evaluate structure, daylight, acoustics, circulation, and cost simultaneously, generating module layouts that work in principle and practice. Instead of one idea per day, teams scan hundreds, then refine the few that respectfully balance fabrication, safety, and human comfort.

Generative Beginnings: Concept Design Reimagined

On a narrow infill site, we used an AI generator to test courtyard voids for daylight and cross-ventilation without sacrificing repeatable bathroom pods. The tool surfaced a hybrid corridor scheme that cut our iteration loops in half and improved acoustic separation.

Semantic BIM enrichment

AI classifies elements, tags tolerances, and infers missing metadata needed for shop drawings, CNC, and procurement. It translates design intent into machine-ready signals, reducing rework and the classic last-mile scramble before panels, frames, and pods go into fabrication.

Predictive clashes and fit-up foresight

Beyond simple clash detection, models learn which conflicts actually matter in modular interfaces: lifting lugs, gasket overlaps, MEP quick-connects, and tolerance stacking. Flagging these early saves hours on-site and preserves the rhythm of assembly crews.

Comment your toolchain wish list

Which authoring tools, file formats, and factory systems do you juggle today? Share your stack and pain points so we can test mappings, propose adapters, and publish repeatable workflows that carry design fidelity all the way to the line.

Designing for Sustainability and Carbon

While exploring module families, the system estimates material quantities, transport impacts, and connector intensity. Designers see carbon deltas in real time, guiding swaps from heavier frames to smarter hybrids and encouraging high-reuse details at module-to-module joints.

Designing for Sustainability and Carbon

Predictive models simulate thermal bridges at seams, mechanical zoning per module, and daylight penetration around stacked masses. The results inform façade kits and services trunks that reduce energy while keeping the factory’s repeatability intact.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Assured Quality and Seamless Assembly

Cameras validate stud spacing, MEP penetrations, and sealant continuity against templates. Deviations trigger immediate fixes, not end-of-line surprises, so module interfaces remain crisp and assembly crews trust every lift to fit.

Models turn the design into step-by-step lifts, alignments, and fastener patterns that match crew capacity. Clear sequences reduce miscommunication and help new team members learn modular specifics without slowing the day.

Which recurring defects drain your budgets—out-of-plumb frames, scratched panels, or misaligned quick-connects? Share details and we’ll craft AI checklists and vision baselines you can adapt to your own modules.

Code reasoning that explains itself

Language models can map design decisions to applicable modular codes, cite sections, and summarize rationale. But they must provide sources and uncertainty so licensed professionals can review, sign, and remain accountable for life-safety outcomes.

Data stewardship for sensitive projects

Training sets need clean boundaries around client IP, site security, and personal data. Establish governance that isolates proprietary BIM models while still enabling learning on generalized patterns like joints, tolerances, and module families.

Join the standards discussion

Comment with your jurisdictional hurdles and certification processes. We will collect examples and work toward open prompt templates and audit trails that make approvals faster without diluting professional responsibility.

Adaptive Futures: Modular Buildings That Learn

Occupancy, acoustics, and comfort data guide swaps of partitions, service pods, and façade cassettes. Instead of renovations that reset everything, owners make targeted moves that preserve modules and extend the building’s useful life.